Drilling mud classification

Drilling muds can be classified into 8 main groups based on their application.

Weight control group or densifiers: densifiers are used to control the density of the mud and prevent gas and oil substances from escaping and the collapse of the well wall. The most used ingredients in the group of densifiers are mainly barite and hematite (ferobar) with high specific gravity.

Viscosity control group or viscosifiers: viscosifiers are used to control the consistency and concentration of the wells mud. And it increases the adhesion and viscosity of the mud. Viscosity is one of the important and key parameters of drilling mud. Viscosifier material increases mud adhesion and keeps suspended solids from drilling inside. Bentonite and xanthan gum are mainly used to increase the viscosity of drilling mud.

PH controller material of the drilling mud: These materials are used to prevent the decrease of the pH of the wells mud, because the acidification of the drilling mud causes the corrosion of the drilling equipment and drills, as well as the reduction of the performance of the soluble materials in the mud. Drilling mud performs better in alkaline environments.

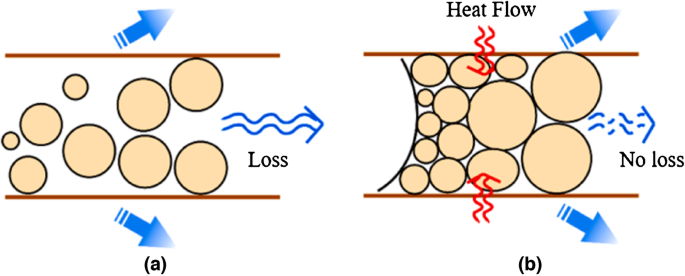

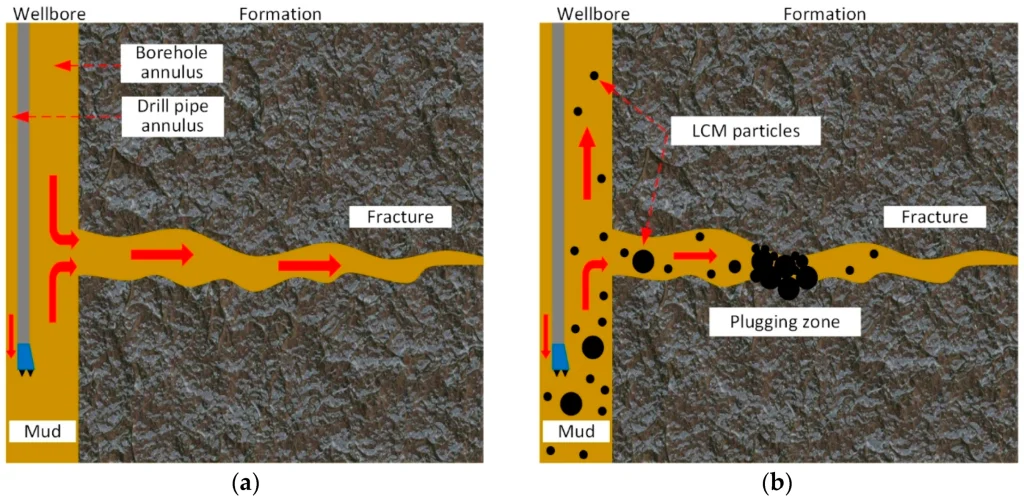

Lost control materials (LCM): These materials are mainly a combination of several materials that reduce the mud loss by settling on the well cavities and clogging the well cavities. Mud contamination is one of the most challenging issues for drilling engineers, because the increase in well mud leads to an increase in the consumption of drilling mud and, as a result, an increase in well costs.

loss Control Materials: These materials also prevent mud wetting by increasing the absorption of water and fluid and increasing the adhesion and concentration of the mud. Mainly, drilling starches are used for this purpose

Salts: Drilling salts mainly prevent water absorption by shale (rocks containing oil). And it prevents the ionization of some materials in the mud.

Shale controlling materials: Shales are rocks with petroleum compounds. The shale control material prevents the dissolution of shale rocks that contain petroleum compounds in the mud. Because sometimes the dissolution of these stones and the oil inside them in the well mud reduces the performance of drilling mud.

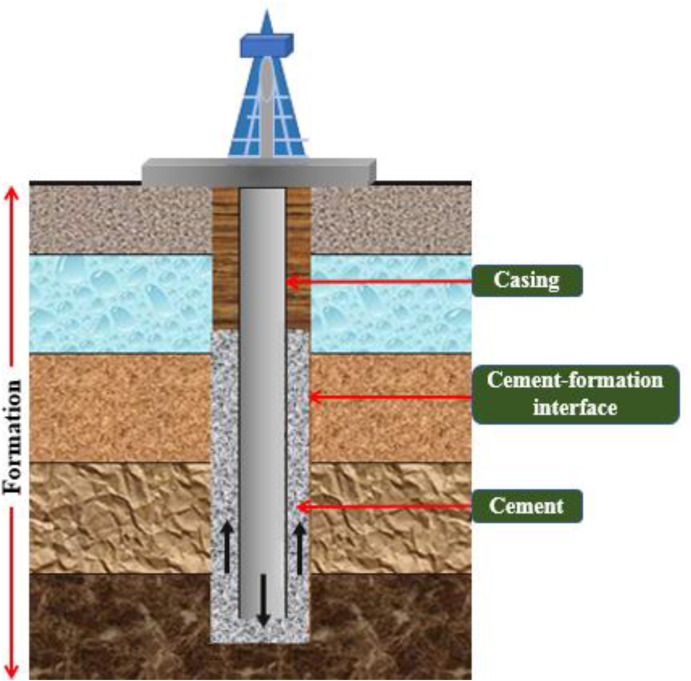

Drilling cement: Drilling cements have various types and compositions. Drilling cement is used to strengthen the well wall and prevent it from falling. There are active drilling cementing specialists for each well.