Quality Control

Check and test of Conducting density, viscosity, Yeild point , gel strength tests by internationally approved laboratories

Logistics

Wide range of logistics and transportation services, including truckload, intermodal, ocean, and air freight.

International Commercial

Kardoost company is one of the best and exprienced Exporter, importer and supplier of all drilling Mud add-ons in middle east

drilling additives service provider

complete line of drilling fluids and additives for every stage of water well drilling.

About us

Kardoost is the largest certified company of Specialty Drilling Fluid Additives, Mud Chemicals, Cementing Additives, Mining Chemicals and Horizontal Drilling Fluids based Middle East. We are Drilling Fluids Additive manufacturer for the Oil and Gas Drilling and Exploration, Mining Industry, Horizontal Drilling Industry. We are the preferred supplier for most Drilling contractors and Service Companies. Our Products are manufactured and Supplied to over 20 Countries in all 5 continents

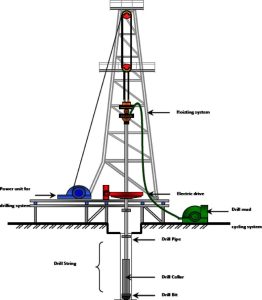

drilling mud

Drilling fluid or drilling mud can be defined as the fluid that circulates in the oil well during the drilling operation.It comes out and after passing through the drilling string and drill, it returns to the surface through the inner annular oil well space. Drilling fluid is the most important and main part in drilling operations Because without drilling fluid, drilling operations will not be possible.The most important tasks of drilling fluid are as below. ·Removing drilling cuttings & particles from inside the well (cleaning the bottom of the well) (bring cuttings to the surface) ·Subsurface pressure control of the well· Suspending drilling chips and releasing them on the surface· Creating a solid layer on the well wall· Creating stability in the well·

Products

Our Team

Ms Soheila Niazi

Financial Manager

Mr Mohamad Dastanpoor

Legal Department

Ms Zahra Rahimi

Financial Department

Mr Vahid Dezfuli

Engineering Department

Mr ashkan adibi

R&D Department

Ms Elham Safari

Commercial Manager

Mr Mohamad Nemati

Mineral Department

Ms Elham Smailzadeh

Commercial Department

Mr Mehdi Sfahani

Administrative Department

Mr Mohmad Noudoost

Kardoost Manager

Mr Amir Hariri

Steel Department

Ms Shima Behzadi

Digital Marketing Department• Drilling mud classification

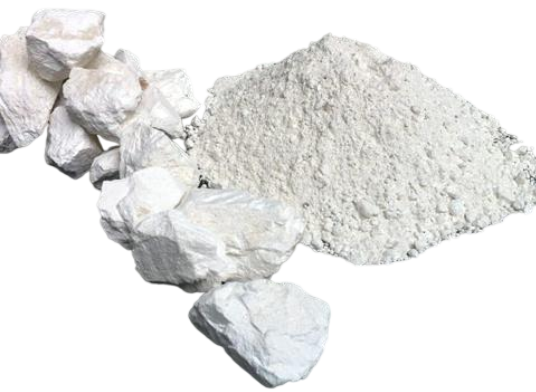

1- Weight control group or densifiers

densifiers are used to control the density of the mud and prevent gas and oil substances from escaping and the collapse of the well wall. The most used ingredients in the group of densifiers are mainly barite and hematite (ferobar) with high specific gravity.

2- Viscosity control group or viscosifiers

viscosifiers are used to control the consistency and concentration of the wells mud. And it increases the adhesion and viscosity of the mud. Viscosity is one of the important and key parameters of drilling mud. Viscosifier material increases mud adhesion and keeps suspended solids from drilling inside. Bentonite and xanthan gum are mainly used to increase the viscosity of drilling mud.

3- PH controller material of the drilling mud

These materials are used to prevent the decrease of the pH of the wells mud, because the acidification of the drilling mud causes the corrosion of the drilling equipment and drills, as well as the reduction of the performance of the soluble materials in the mud. Drilling mud performs better in alkaline environments.

Blog

address

504unit, Kowsar complex, Charbagh bala street, Isfahan city, Iran

Phone Call

0098-3136205310

info@drillingfluidco.com